Difference Between Audi A4 Front Track and Quattro Transmission Mounts?

| | |

| Type | Sectionalisation |

|---|---|

| Manufacture | Automotive |

| Founded | 1980 |

| Headquarters | Germany |

| Area served | Worldwide |

| Owner | Volkswagen Group |

| Parent | Audi |

quattro (pregnant four in Italian) is the trademark used by the automotive brand Audi to indicate that all-bike drive (AWD) technologies or systems are used on specific models of its automobiles.[1]

The word "quattro" is a registered trademark of Audi AG, a subsidiary of the German automotive business organization, Volkswagen Group.[1]

Quattro was kickoff introduced in 1980 on the permanent four-wheel drive Audi Quattro model, oft referred to as the Ur-Quattro (significant "original" or "first"). The term quattro has since been applied to all subsequent Audi AWD models. Due to the nomenclature rights derived from the trademark, the discussion quattro is at present always spelled with a lower case "q", in honour of its former namesake.

Other companies in the Volkswagen Group have used different trademarks for their 4WD vehicles. While Audi has always used the term "quattro", Volkswagen-branded cars initially used "syncro", just more recently, VW uses "4motion". Škoda just uses the nomenclature "4x4" after the model name, whereas SEAT uses simply "iv" ("4Drive" more recently). None of the to a higher place trademarks or nomenclatures defines the operation or type of 4WD organisation, as detailed below.

Longitudinal systems [edit]

Volkswagen Group has been developing four-bicycle bulldoze (4WD) systems about since its inception during the 2d Earth War. The Volkswagen Kübelwagen, Volkswagen Schwimmwagen, and Volkswagen Kommandeurswagen were all armed services vehicles which required all four road wheels to be "driven", the latter being a 4WD Volkswagen Beetle. Their military and four-wheel drive experiences later aided them in designing the Volkswagen Iltis for the German military (Bundeswehr) in the 1970s. The Iltis utilized an early on form of 4WD, which would later on get synonymous with "quattro".[two]

Locking centre differential [edit]

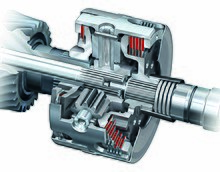

In that original quattro system, later on found in route-going rider cars, the engine and transmission are situated in a longitudinal position. Torque is sent through the transmission to a mechanical centre differential[3] (commonly abbreviated to "unequal") which apportions (distributes) the torque between front and rear driven axles. 4WD was permanently agile.

The Torsen T1 centre differential [edit]

After 1987, Audi replaced a manually locking heart differential with the Torsen (torque sensing) Type 1 ("T1") middle differential. This allowed engine torque to be automatically directed to private axles as driving conditions and grip warranted. Under 'normal' conditions (where grip in both front and rear axles is equal), torque is split between front and rear with a 'default" l:50 distribution in many, though non all, versions. In adverse conditions (i.e., when there is variation in grip between front and rear), a maximum of 67-80% (depending on the manual, or model of Torsen diff) of the engine'south torque can exist directed to the front or rear axles. The fully automatic mechanical nature of the Torsen heart differential helps preclude wheel slippage from occurring, by diverting torque instantly, without any discernible notice to the vehicle occupants,[4] to the axle which has more grip. This method of operation tin can be described as proactive. Furthermore, unlike the various types of electronically operated differentials, Torsen has no requirement for electronic information from sources such as route wheel speed sensors; information technology, therefore, has an element of "neglect-prophylactic", dissimilar designs such as Haldex Traction, should one of the wheel speed sensors develop a fault. In comparison, viscous coupling and electronically controlled centre differentials that are used in other four-wheel drive systems are reactive, since they merely redirect torque after bicycle slippage has occurred. The reward is felt nether hard dispatch, including whilst cornering, since the torque transfer betwixt axles is seamless, thus maintaining stable vehicle dynamics, and considerably reducing the run a risk of losing command of the vehicle.

The Torsen-based quattro system also offers an advantage in the opposite role of distributing torque to the route wheels, namely engine braking. When engine braking is used to ho-hum the motorcar down, with Torsen-based systems, the resulting "reverse-torque" loads on the front and rear axle are as stabilized, in exactly the same way that engine "propulsion" torque is apportioned fully mechanically autonomously. This allows the spreading of the engine braking outcome to all four wheels and tyres. The Torsen-based quattro-equipped vehicle is able to execute a more stable high-speed turn under deceleration, with less gamble of losing control due to loss of grip in the forepart or rear axles.

This configuration of the quattro system, all the same, does take some limitations:

- With placement of the engine and transmission assembly in a fore/aft position (longitudinally), the front axle is placed rearwards behind the engine, which leads to the criticism of some Audi vehicles as beingness nose heavy. This results in a weight distribution of 55:45 (F:R).

- The nature of the Torsen is alike to that of a limited skid differential in that, rather than actively allocating torque (as a reckoner controlled clutch tin can do), it supports a torque divergence across the differential (the torque bias ratio/TBR), from the side with the least grip to the side with the well-nigh. Hence past nature the Torsen is limited in the amount of torque that can be supplied to the beam with the most grip by the torque bachelor at the beam with the least amount of grip. Therefore, if one beam has no grip, regardless of the TBR, the other axle volition not exist supplied substantial torque. In the extreme, for a centre differential implementation, complete loss of traction on a single wheel volition outcome in very limited torque to the other three wheels. Audi responded to this limitation for the beginning Torsen-equipped cars by calculation a manually locking rear differential and and so later replaced this characteristic with Electronic Differential Lock (EDL), which is the ability to use the individual wheel brakes (monitored past the ABS sensors) to limit individual wheel spin. EDL was implemented across both front and rear (open up) differentials to operate at speeds less than fourscore km/h. This has the effect of increasing torque from a single low-traction wheel hence assuasive more than torque to be passed past the Torsen to the remaining loftier-traction wheels.

- While the standard (Type 1 or T1) Torsen supports a static torque ratio of l:fifty; i.due east., input torque is supported every bit beyond both output shafts, the T1 has a Torque Bias Ratio (TBR) of 2.7–4:1; i.e., it allows almost 3 to 4 times the torque to exist supplied to the most tractive output shaft than that is available on the to the lowest degree tractive shaft or, a torque split of between 25% to 75%. However, by nature the T1 Torsen is locked under most circumstances (output shafts locked together). Just when the TBR is reached (i.eastward., there is a greater torque difference across the output shafts than can exist supported by the TBR) exercise the output shafts plough relative to each other, and the differential unlocks. This characteristic results in a relatively gratis torque movement between both outputs of the (centre) differential, within the limits of the TBR. Thus the static torque distribution of the T1 Torsen in a centre differential installation, rather than being 50:50, will mirror the weight distribution (both static and dynamic) of the vehicle due to the traction available at either (forepart:rear) output shaft. In a standard car, this is desirable from the perspective of stability, dispatch and traction, but can be undesirable in terms of handling (understeer). While the standard quattro Torsen T1 with ii.7:1 TBR is more than than sufficient in most atmospheric condition, Torsen T1 differentials with higher TBRs (4:1) are available and can further limit understeer by supporting a wider torque split up. A better solution, yet, is to apportion a torque split directly between both output shafts (front & rear) and for this reason Audi has adopted the Type 3 (T3) Torsen design in the latest generations of quattro.

The Torsen type "C" (T3) [edit]

The Torsen T3 centre differential combines a planetary gear set with a Torsen differential in a meaty parcel developed for centre differential installations. Different the T1 Torsen where the torque split is a nominal 50:50, in the T3 Torsen the torque split up, due to the use of the planetary gear set, is an asymmetric 40:60 front-rear torque carve up (i.e., when grip is equal on both front and rear axles, 40% of torque is sent to the front axle, and 60% to the rear). As with the T1 Torsen, torque will exist distributed dynamically depending on tractive conditions, but with an bodily (rather than nominal) static bias. The T3 allows handling characteristics and vehicle dynamics more akin to rear-bike drive cars. This asymmetric Torsen was first introduced in the highly acclaimed 2006-model (B7) Audi RS4. The Type 3 torsen was used in the Audi S4 and RS4 B7 manual transmissions from 2006 to 2008, likewise as the S6, S8, and Q7 models from 2007.

The torque split beyond axles and betwixt left and right wheels has been achieved through the diverse evolutions of the quattro system, through a driver-selectable manually locking differential (rear axle only), and eventually through open differentials with Electronic Differential Lock (EDL). EDL is an electronic system, utilising the existing anti-lock braking system (ABS), function of the Electronic Stability Plan (ESP), which brakes simply the one spinning wheel on an axle, therefore assuasive the transfer of torque across the beam to the wheel which does accept traction.[five]

Crown-wheel centre differential [edit]

Audi debuted a new generation of quattro in the 2010 RS5. The key modify is the replacement of the Torsen Type "C" heart differential with an Audi-developed "Crown Gear" differential. Whilst this is superficially the same as a normal open up differential, adapted for a centre awarding, it has some central differences:

- The central carrier and associated spider gears interface directly to 2 crown wheels connected to the front and rear drive shafts

- The two crown wheels interface to the spider gears at unlike diameters, and so produce different torque when turned past the spider gears. This is engineered to produce a twoscore:lx static torque split front and rear.

- Each crown cycle interfaces to the corresponding output shaft straight, whilst the spider carrier interfaces to each output shaft using a clutch pack which gives the unit the ability to control torque distribution over and above the static torque distribution.

If i axle loses grip, dissimilar rotational speeds arise inside the differential which outcome in an increase in centric forces that force the clutch plates to close. Once closed, the output shaft is locked resulting in the diversion of the majority of the torque to the axle achieving amend traction. In the Crown Gear differential upwards to 85% of torque tin can period to the rear, and upwardly to 70% of torque tin exist diverted to the front axle.

The features of the Crown Gear differential provide the following benefits over the Torsen Type "C"

- The ability to prepare upward a more than stable torque distribution, with full locking whereas the Torsen can merely provide a torque distribution upwards to the Torque Bias Ratio; i.e., the Crown Gear differential tin lock fully, regardless of bias ratio. Dissimilar the Torsen, the Crown Gear differential does not operate like a limited slip differential and can operate, fully locked, with no traction on 1 output shaft.

- Easier integration into control electronics allowing four-wheel electronic torque vectoring with or without the agile rear sport differential

- Considerable reduction in size and weight (at 4.8 kg, some ii kg lighter than the Torsen Type C)

The net result of this advance in quattro is the ability of the vehicle electronics to fully manage the vehicle dynamics in all traction situations, whether in cornering, acceleration or braking or in whatever combination of these.

Evolutions [edit]

Audi has never officially debuted quattro in specific generations. Changes to quattro applied science have mostly been debuted with a specific range or model in the range and so brought into other models during appropriate points in the model bike.

The exception to the to a higher place was the debut of the 2010 RS5 which was, among other things, heralded past Audi equally the debut of a "new generation of quattro".

quattro generation I [edit]

Sit-in of the first quattro generation.

Used from 1981 to 1987 in Audi Quattro turbo coupé, Audi 80 B2 platform (1978–1987, Audi 4000 in North American market), Audi Coupé quattro B2 platform (1984–1988), Audi 100 C3 platform (1983–1987, Audi 5000 in North American market). Also, starting from 1984, used on the Volkswagen VW Passat B2 platform (VW Quantum in the US marketplace) where it was known as Syncro.

System type: Permanent 4-wheel bulldoze.

Open up centre differential, manually lockable via switch on eye console.¹

Open up rear differential, manually lockable via switch on heart console.¹

Open forepart differential, no lock.

¹ABS disabled when locked.

How the arrangement performs: When all differentials are unlocked, the car volition not exist able to move if one bicycle (front end or rear) loses traction (is on ice or raised in the air). When the center differential is locked with the rear differential unlocked, the car will non exist able to move if i forepart wheel and one rear wheel lose traction. When the rear differential is locked with the centre unlocked, the car will not exist able to motility if both rears or one front loses traction. When both middle and rear differentials are locked, the motorcar will not be able to move if both rears and 1 front lose traction.

quattro generation II [edit]

Starting from 1988 on older generation Audi 100 C3 platform and Audi Quattro until the end of their product, and on new generation B3 platform (1989–1992) Audi 80/ninety quattro, B4 platform (1992–1995) Audi fourscore, Audi S2, Audi RS2 Avant, C4 platform (1991–1994) Audi 100 quattro, Audi S4, after C4 platform (1994-1997) Audi A6/S6.

System blazon: Permanent 4-wheel bulldoze.

Torsen centre differential, 50:50 'default' carve up, automatically apportioning upward to 75% of torque transfer to either axle.

Open rear differential, manually lockable via switch on eye console located next to handbrake.¹

Open front differential, no lock.

¹ABS disabled when locked, automatically unlocks if speed exceeds 25 km/h (16 mph).

quattro generation Three [edit]

Used only on the Audi V8 starting from 1988 to 1994.

System type: Permanent four-wheel drive.

V8 with automatic transmission:

Planetary gear centre differential with electronically controlled multi-plate locking clutch

Torsen blazon one differential rear.

Open up differential forepart.

V8 with transmission transmission:

Torsen type 1 centre differential.

Torsen type 1 rear differential.

Open front differential.

How does the system perform: In on-road conditions the car will non be able to motion if i front and both rear wheels lose traction altogether.

quattro generation Four [edit]

Starting from 1995 on Audi A4/S4/RS4 (B5 platform), Audi A6/S6/allroad/RS6, Audi A8/S8 with both manual and automatic transmissions. As well on VW Passat B5, where it was initially referred to as syncro, but by the time it reached U.s. soil, it had been re-christened 4motion.[six] Also used on the Volkswagen Phaeton and Volkswagen Grouping D platform sister vehicles. The Volkswagen Touareg used 4Xmotion with a split up transmission, PTUs and front axles.

The manually locking rear differential from the earlier generations was replaced with a conventional open differential, with Electronic Differential Lock (EDL) (which detects wheelspin via ABS road bicycle speed sensors, and applies brakes to one spinning wheel, thus transferring torque via open differential to the opposite wheel which has more traction). EDL works at speeds upwardly to 80 km/h (50 mph), on all quattro models (on not-quattro models: up to 40 km/h (25 mph)).

System type: Permanent iv-wheel drive.

Torsen type 1 centre differential, 50:50 'default' split, automatically apportioning up to 75% of torque transfer to either front or rear axle.

Open up rear differential, Electronic Differential Lock (EDL).[5]

Open front differential, Electronic Differential Lock (EDL).[5]

quattro generation V [edit]

Starting with the B7 Audi RS4 and the manual transmission version of the 2006 B7 Audi S4. Information technology was adopted in the entire S4, S6, and S8 lineup in 2007.[1]

Arrangement type: Permanent asymmetric four-cycle drive.

Torsen type 3 (Type "C") centre differential, xl:60 'default' split front-rear, automatically apportioning upwards to 80% of the torque to ane axle using a 4:1 high-biased center differential. With the help of ESP, up to 100% of the torque can be transferred to one axle.

Open rear differential, Electronic Differential Lock (EDL).[5]

Open front differential, Electronic Differential Lock (EDL).[5]

Vectoring quattro system [edit]

Audi'due south new sport differential, debuted 'torque vectoring' to quattro generation 5. The Audi sport differential allowed the dynamic allocation of torque across the rear beam of the debut vehicle: the B7 (2008) S4, and is now an optional add-on to all quattro vehicles, which keep to use the 40:60 asymmetric Torsen (Type "C") centre differential. The sport differential replaces the normal open up rear differential while the front axle notwithstanding rely on an open differential with EDL.[v]

The torque vectoring rear beam differential is designed and manufactured past Magna Powertrain,[7] and is being offered on Audi A4, A5, A6 and their derivatives (including RS models). The Sport Differential selectively distributes torque to the rear axle wheels thereby generating a yaw moment, which improves handling and also stabilizes the vehicle when information technology oversteers or understeers, thereby increasing prophylactic.

The sport differential operates by using two superposition ("step upward") gears at the differential, which are operated via multi-plate clutches each side of the differential crown wheel. When required by the software (using lateral and longitudinal yaw sensors, the ABS wheel sensors, and a steering cycle sensor), the control software (located in a control unit shut to the rear differential), actuates the relevant clutch pack. This has the effect of taking the output shaft drive through the step-up gear to the attached cycle, while the other shaft continues to drive its wheel directly (i.due east., the clutch pack not actuated). The higher speed output shaft produces increased torque to the bike, producing a yaw (turning) moment. In normal performance increased torque is delivered to the wheel on the outside of the turn thereby increasing the vehicles turning moment, in other words, its willingness to turn in the direction pointed past the steering wheel.

quattro generation VI [edit]

Audi debuted the 6th generation of quattro in the 2010 RS5. The fundamental alter in generation VI is the replacement of the Torsen Type "C" heart differential with an Audi-developed "Crown Gear" differential. With the new "Crown Gear" center differential, upwards to seventy% of the torque can be applied to the front end wheels while upwardly to 85% can be applied to the rear wheels if necessary. The net result of this advance in quattro is the ability of the vehicle electronics to fully manage the vehicle dynamics in all traction situations, whether in cornering, acceleration, braking, snow or in any combination of these. This organization was later adopted by the A7, latest generation of the A6 and A8.

BorgWarner [edit]

The Audi Q7, the platform-mate of the Volkswagen Touareg and Porsche Cayenne, does non apply the same underpinnings of either previous model. BorgWarner instead provides the 4WD system for this more off-road appropriate SUV. A Torsen Type 3 (T3) differential is used.

Ultra [edit]

Audi announced "Audi Quattro with Ultra Technology" in Feb 2016, it is a front end-cycle drive biased arrangement for use on platforms with longitudinally mounted engines, and shares much in common with their Haldex based systems.[8]

Transverse systems [edit]

Since Volkswagen Grouping's first mainstream transverse engined vehicle in 1974, four-bike bulldoze (4WD) has also been considered for their A-platform family of cars. It was not until the second generation of this platform that 4WD finally appeared on the market. The mid-1980s Mk2 Golf syncro, with its transverse engine and transmission positioning, had nearly of its torque sent primarily to the front end axle.

Fastened to the transaxle is a Power Transfer Unit of measurement (PTU), which is continued to a rear beam through a propeller shaft. The PTU also feeds torque through itself to the forepart axle. At the rear axle, torque was outset sent through a sticky coupling earlier reaching the final drive gearset. This coupling contained friction plates and an oil just glutinous enough and so that pressure affected how many plates were connected and active (and therefore, how much power was being delivered to the rear wheels).

Starting with the Mk4 generation A4-platform, the sticky coupling has been dropped in favour of a Haldex Traction electro-hydraulic limited-slip "coupler" (LSC) or clutch. The Haldex Traction LSC unit is not a differential and therefore cannot perform in the true sense similar a differential. A Haldex Traction unit of measurement may divert up to a maximum 100% of the torque to the rear axle as conditions warrant. Many people[ who? ] are confused with the torque distribution on Haldex-based systems. Nether normal operating conditions the Haldex clutch operates a charge per unit of v% torque manual. Under adverse weather condition where the machine'due south road cycle speed sensors have determined that both front wheels accept lost traction, the Haldex clutch can lock at 100% clamping force, meaning all torque is transferred to the rear beam. The torque dissever betwixt left and right wheels is achieved with a conventional open up differential. If one side of the driven beam loses grip, then the Electronic Differential Lock (EDL) component of the ESP controls this. EDL brakes a single spinning wheel; therefore, the torque gets transferred beyond the beam to the opposite bicycle via the open differential. On all transverse engine cars with the Haldex-based 4 wheel drive arrangement, the EDL only controls forepart wheels, and not the rear.

The main advantages of the Haldex Traction LSC organisation over the Torsen-based organization include: a slight gain in fuel economy (due to the decoupling of the rear axle when not needed, thereby reducing driveline losses due to friction), and the ability to maintain a short engine bay and larger passenger compartment due to the transverse engine layout. A further advantage of the Haldex, when compared to just front cycle drive variants of the same model, is a more than balanced front end-rear weight distribution (due to the location of the Haldex center "differential" next to the rear beam).

Disadvantages of the Haldex Traction system include: the vehicle has inherent front-cycle drive handling characteristics (as when engine braking, load is only applied on the front wheels, and due to the reactive nature of the Haldex system and slight lag time in the redistribution of engine power), and the Haldex LSC unit too requires additional maintenance, in the form of an oil and filter alter every 60,000 kilometres (37,000 mi) (whereas the Torsen is by and large considered to be maintenance-free). Some other important disadvantage of the Haldex system is the requirement for all four tyres to exist of identical wear levels (and rolling radii), due to the Haldex requiring data from all iv route cycle speed sensors. A terminal significant disadvantage is the reduction in luggage capacity in the boot (trunk), due to the beefy Haldex LSC unit of measurement necessitating a raised boot floor by some three inches.

Glutinous coupling [edit]

This 4WD system was used only on Volkswagen branded vehicles, and was never used on any Audi cars except Audi R8 model.

The aforementioned viscous coupling 4WD system was found in the Mk2 generation of transverse-engined A2-platform vehicles, including the Volkswagen Golf Mk2 and Jetta. It was also found on the Volkswagen Type 2 (T3) (Vanagon in the US), Mk3 generation of Golf and Jetta, third generation of Volkswagen Passat B3 (which was based on a heavily revised A-platform), and the Volkswagen Eurovan.

The Vanagon system was RWD-biased, the engine and transaxle were in the rear, whereas the pasty coupling was constitute in the front end axle near the final drive. This 4WD system was known as Syncro on all vehicles.

What: Automatic four bicycle bulldoze (on demand).

A gluey coupling installed instead of a centre differential, with freewheel mechanism to disconnect the driven axle when braking.

Open rear differential (mechanical differential lock optional on Vanagon).

Open front differential (mechanical differential lock optional on Vanagon).

Commonly a front-wheel drive vehicle (except Vanagon, see to a higher place). In normal driving conditions, 95% of torque is transferred to front beam. Because pasty coupling is considered to be "slow" (some time is needed for silicone fluid to warm-up and solidify), five% of torque is transferred to rear axle at all times to "pre-tension" the viscous coupling and reduce activation time. The coupling locks when slipping occurs and upwards to almost 50% of torque is automatically transferred to rear beam (front in Vanagon). In on-road conditions, the auto will not movement if 1 forepart wheel and ane rear bike lose traction.

The freewheel segment, installed inside the rear differential, lets rear wheels rotate faster than front wheels without locking the viscid coupling and preventing ABS from applying brakes to each bike independently. Because of the freewheel, torque can be transferred to rear beam only when the vehicle is moving forrad. For 4-bike drive to piece of work when reversing, a vacuum-actuated "throttle control element" is installed on the differential case. This device locks the freewheel mechanism when in contrary gear. The freewheel machinery unlocks when the gear-shift lever is pushed to the correct, past the tertiary gear. The freewheel is not unlocked immediately after leaving opposite gear on purpose – this is to preclude the freewheel from cycling from locked to unlocked if the car is stuck and commuter is trying to "rock" the automobile by irresolute from beginning to opposite and back.

Disadvantages of this four-wheel drive organization are related to actuation time of the viscous coupling.

- When cornering under acceleration on a slippery surface, the rear axle is engaged with delay, causing sudden modify in the car's behaviour (from understeer to oversteer).

- When starting on a sandy surface, the front end wheels tin can dig into the sand earlier all-wheel bulldoze is engaged.

Haldex [edit]

Starting from 1998, the Swedish Haldex Traction LSC unit of measurement replaced the viscous coupling. Haldex is used by Audi on the quattro versions of the Audi S1, Audi A3, Audi S3, and the Audi TT. It is too used past Volkswagen in the 4motion versions of the Mk4 and Mk5 generations of Volkswagen Golf, Volkswagen Jetta, and the Golf R32, Volkswagen Sharan, 6th generation VW Passat (besides based on the A-platform) and Transporter T5. On the Audis, the trademark holds, and are still referred to equally quattro, whereas the Volkswagens receive the 4motion name. The Škoda Octavia 4x4 and SEAT León 4 and SEAT Alhambra iv as well used Haldex LSC, existence based on Volkswagen Group models. Curiously, the Bugatti Veyron also utilizes Haldex, though with separate manual, PTU and front and rear axles.

What: Automated four wheel drive (on demand).

Haldex Traction LSC multi-plate clutch with ECU electronic command, interim every bit a pseudo eye differential.

Open rear differential, no EDL.

Open forepart differential, EDL.

How: Normally front-bicycle bulldoze vehicle. A Haldex Traction LSC unit may divert up to a maximum 100% of the torque to the rear beam as conditions warrant. Many people find the torque distribution on Haldex Traction systems confusing. Nether normal operating conditions, the Haldex LSC clutch operates at five% (divide 5% between front and rear, and 97.v% torque goes to the front, and ii.5% goes to the rear). Nether adverse conditions where both front wheels lose traction, the Haldex clutch tin can lock at 100% clamping force. This means, that since there is no torque transferred to the front end axle, all torque (minus losses) must be transferred to the rear beam. The torque split between left and right wheels is achieved with a conventional open differential. If ane side of the driven axle loses grip, then the Electronic Differential Lock (EDL) controls this. EDL brakes a single spinning bicycle, and therefore torque gets transferred to the opposite bicycle via the open up differential. On all transverse-engined cars with the Haldex Traction LSC 4-cycle drive organization, the EDL only controls the forepart wheels, and not the rear.

In vehicles equipped with EDL on the front wheels only, the car will not move if both front and one of the rear wheels loses traction.

Again, due to limitations of Electronic Differential Lock (see quattro 4 clarification to a higher place), in off-route conditions it is enough for one front end and ane rear wheel to lose traction and the car will not move.

The Haldex Traction system is more than reactive than preventative, in that there must be a divergence in sideslip (or rotational speed) of the two axle systems before the Haldex operates and sends torque to the rear axle. This is not the same every bit wheel spin, every bit the organization tin can react in less than the full rotation of whatsoever bicycle on the vehicle. The Torsen'due south permanent 'full-time' fifty-fifty torque split nether not-slipping conditions makes slipping less probable to start.

The Haldex Electronic Control Unit of measurement (ECU) disengages the Haldex clutch in the centre coupling equally shortly as brakes are applied to let ABS piece of work properly. When performing tight low-speed turns (due east.g. parking) the clutch is disengaged past Electronic Control Unit to avoid "current of air-up" in transmission. When Electronic Stability Programs (ESP) are activated the Haldex is disengaged to allow the ESP arrangement to finer control the vehicle, this applies under acceleration and deceleration conditions.

Marketing [edit]

As function of Audi's celebration of quattro All-Bike Bulldoze engineering, a Tv set commercial titled 'Ahab' was produced inspired past the American novel, Moby Dick. The ad debuted in the United states during 2012 NFL partitioning playoffs.[ix]

See also [edit]

- 4motion - Volkswagen branded four bike drive system.

- 4Matic - a four-wheel drive system from Mercedes-Benz

- All-Trac - a four-bicycle drive system from Toyota

- ATTESA - a four-wheel bulldoze organisation from Nissan

- Southward-AWC - a torque vectoring all-bike bulldoze organisation from Mitsubishi Motors

- SH-AWD - a torque vectoring all-wheel drive system from Honda

- BMW xDrive - a 4-wheel drive system from BMW

- 4-cycle drive - a history of all-wheel bulldoze in passenger cars

- Symmetrical All Wheel Drive - the four wheel drive system from Subaru

References [edit]

- ^ a b c Audi.com - Glossary quattro Archived 2008-06-22 at the Wayback Car

- ^ Audi of America Printing Site 25 Years of Audi Quattro Archived 2008-06-nineteen at the Wayback Machine 22 February 2005

- ^ Audi.com - Glossary Centre differential Archived 2008-05-xv at the Wayback Machine

- ^ "Audi A Drive". CarDekho . Retrieved 2017-09-08 .

- ^ a b c d e f Audi.com - Glossary Electronic Differential Lock Archived 2008-06-22 at the Wayback Machine

- ^ "What is the drive split on my A4 2.5tdi v6 180bhp". Audi-Sport.cyberspace . Retrieved 2017-09-19 .

- ^ Automobilwoche [ permanent dead link ]

- ^ Tracy, David (2016-02-22). "Audi's Loftier-Tech New Quattro Is About To Piss Off Its Biggest Fans". Jalopnik. Retrieved 2016-02-24 .

- ^ Audi goes all Herman Melville on us to highlight benefits of Quattro

External links [edit]

- Audi.com corporate international portal

- Independent grip. Intelligently practical Audi UK quattro page

DOWNLOAD HERE

Difference Between Audi A4 Front Track and Quattro Transmission Mounts?

Posted by: collinsnoweepubt.blogspot.com

0 Response to "Difference Between Audi A4 Front Track and Quattro Transmission Mounts?"

Post a Comment